WIRO-Spec: An

Integral-Field, Volume-Phase, Holographic Spectrograph(manual

(pdf) (web))

WIRO

Spec is the second of a new generation of facility instruments

developed for the Wyoming Infrared Observatory (WIRO). The

spectrograph was designed by Michael Pierce, Harold Nations and

Philip Haynes. Our primary goal was to provide a high-efficiency

medium-resolution spectrograph for the WIRO 2.3-meter telescope at

low cost. Steve Hodder was the primary machinist for the project and

James Weger developed the electronic design. The instrument is

bench-mounted and located in the spectrograph room. The design

features Volume-Phase-Holographic (VPH) Gratings enabling a total

system efficiency of almost 50%. The optical design features

all-transimission optics with a 345mm f/3.5 collimator and

interchangeable camera lenses mounted on an articulating stage. The

VPH transmission grating is located within these two components and

can be rotated to "scan" in wavelength. With these optics

the 100 um fibers of the 15x20 fiber integral-field unit project to

2.3 pixels with the Marconni/EEV CCD camera (13.5microns/pixel). The

all-transmission design was adopted in order to enable a short

collimated beam. This was necessary to ensure that a long slit (i.e.

lots of fibers) would suffer from little, if any, vignetting losses.

A positive meniscus field lens is located immediately behind the

"slit" to create a geometric pupil at/near the entrance

aperture of the spectrograph camera since this is the element with

the smallest aperture and the most sensitive to vignetting. The

spectrograph is operated in a Littrow configuration since this is the

condition of maximum efficiency for VPH gratings. In this case the

grating equation becomes: nu*lambda=2sin(theta), where nu is the line

frequency (lines/nm) and theta is the incident angle for the grating.

Note that the Littrow condition requires that the camera-collimator

angle be twice the incident angle for the grating (theta). Thus, the

incident angle for the grating can be computed for any desired

wavelength and the camera-collimator angle follows. The telescope is

positioned in order to place a target onto a fiber-optic

integral-field unit. This assembly consists of 293 optical fibers

glued into a hexagonally-packed array of 15x20 fibers each of which

projects to 1 arcsec diameter on the sky. The fiber-optic cable leads

to the bench-mounted spectrograph located on the observatory floor.

At the spectrograph the 293 fibers are formed into a vertical stack

to form a "slit". The spectrograph optics ensure that the

slit is imaged onto the 2048x2048 detector such that the 293 spectra

can be recorded simultaneously. Once the spectra are individually

wavelength calibrated the user can measure velocities, line-ratios,

etc., at any point in the object given the X-Y position of each fiber

in the integral-field array. At present one fiber is broken (#155) is

is hence unusable. Luckily it is located on the edge of the array and

so its impact is negligible.

Guider

Acquisition Assembly (GAM)

Guider

Acquisition Assembly (GAM)

The

Guider Acquisition Assembly (GAM) is located

at the Cassegrain focus of WIRO and contains the integral-field,

fiber optic array, a small ST-237 CCD for guiding and object

acquisition, and the calibration lamps for the spectrograph. Since

the Cassegrain focus of WIRO is f/27, this assembly also contains

0.33X focal reducing optics in order to produce an f/9 beam such that

the image scale is better matched to the size of the optical fibers.

The figure below shows the GAM mounted on the WIRO telescope. Note

the flexible steel conduit containing the fiber-optic cable extending

from the bottom of the GAM. The bungees provides extra slack in the

cable in order to allow the telescope to be positioned to any point

on the sky without undo stress on the fibers.

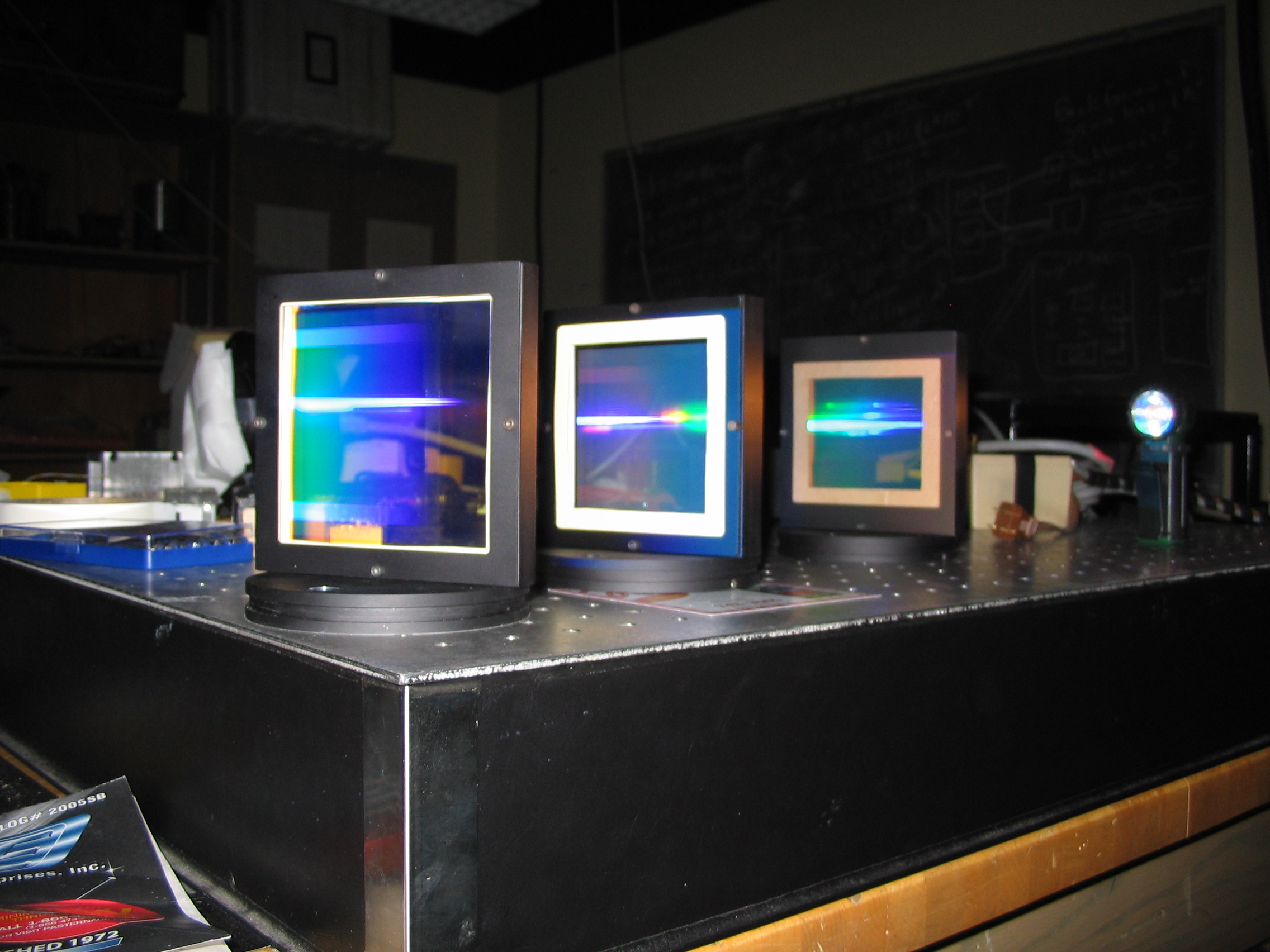

Integral

Field Unit (IFU)

Integral

Field Unit (IFU)

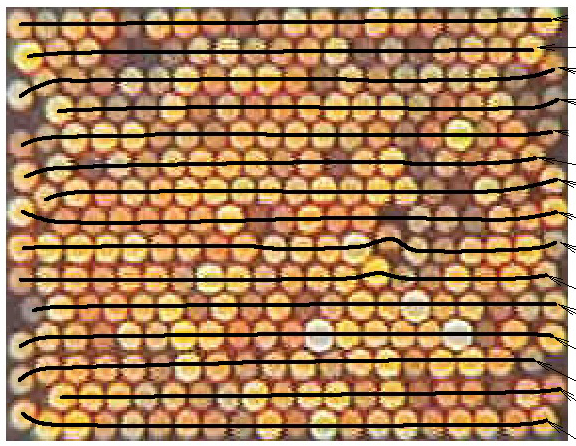

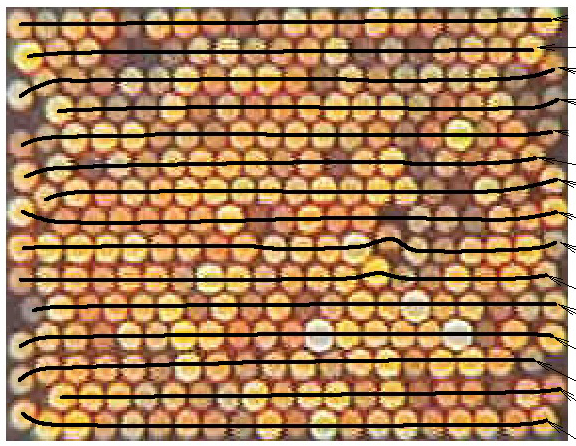

The integral field unit (IFU) of

WIRO-Spec is comprised of a rectangular array of hexagonally-packed

optical fibers. Each 100mm fiber subtends 1.0 arcsec when mounted

behind the 0.33x focal reducer at the Cassegrain focus of WIRO. This

size was chosen as a compromise driven primarily by the 13.5mm pixels

of WIRO-Prime and the desire to minimize vignetting losses due to the

focal ratio degradation from the fibers. The 293 fibers are arranged

into a "15 X 20" array with alternating rows of 20 and 19

fibers. In order to keep the costs of the IFU low, no attempt was

made to map adjacent fibers in the IFU onto adjacent positions along

the slit. The IFU was manufactured by InnovaQuartz

in Phoenix, AZ by gluing each row of

fibers into the IFU assembly. The hexagonally packing of the 120mm

fibers(including the cladding and buffer), results in a 70% packing

fraction for the IFU. At the slit end the fibers were glued into a

slit of 75mm length on 250mm centers. This spacing was chosen

as a compromise between the need for clean separation of the

individual fiber traces on the CCD and the desire to have as many

fibers in the IFU as possible. The figure below shows the back-lit

array and a table of x-y positions vs. slit position(necessary for

the analysis) can be found here.

At the present time one fiber located

on the edge of the IFU is broken (#155).

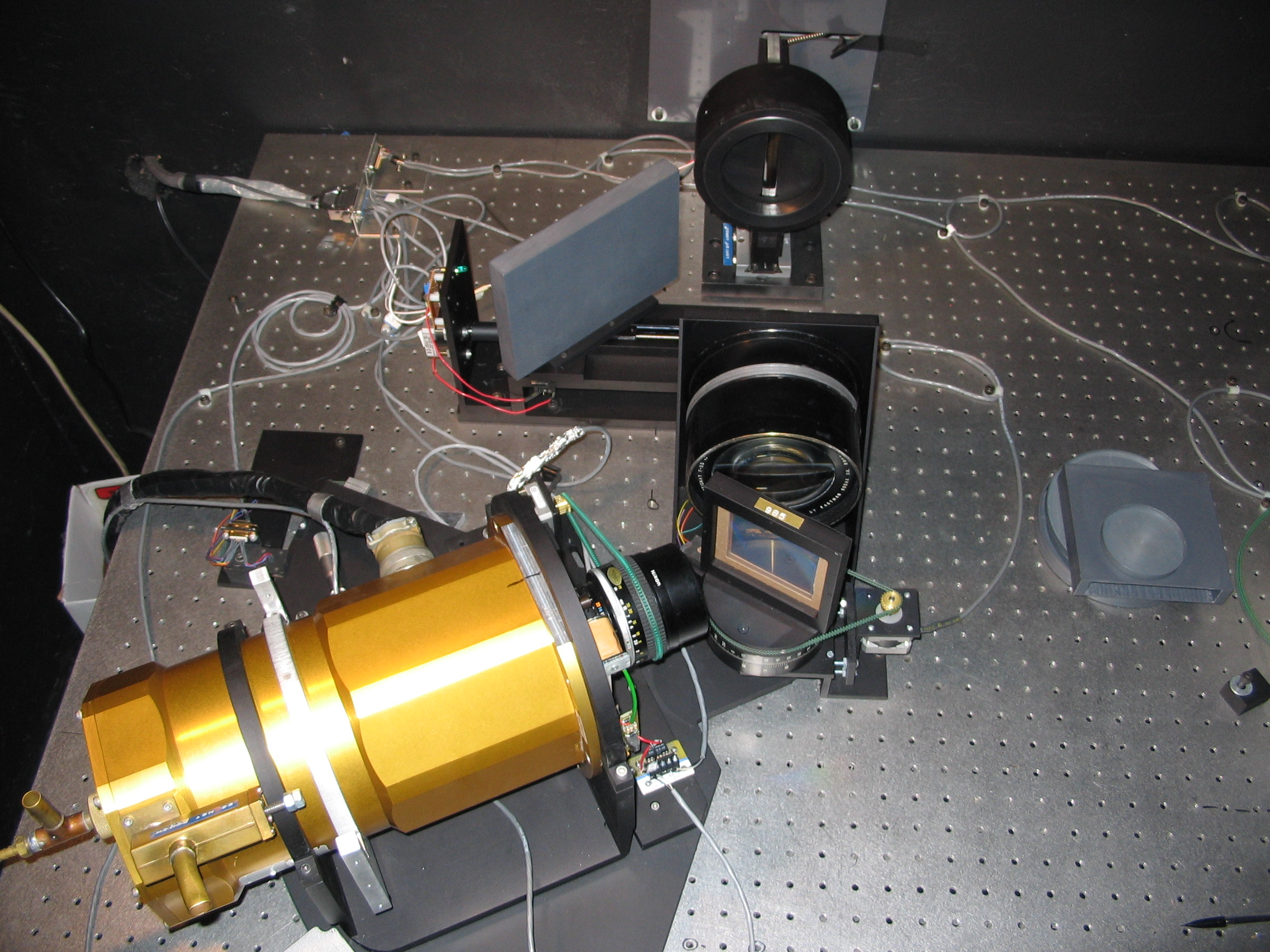

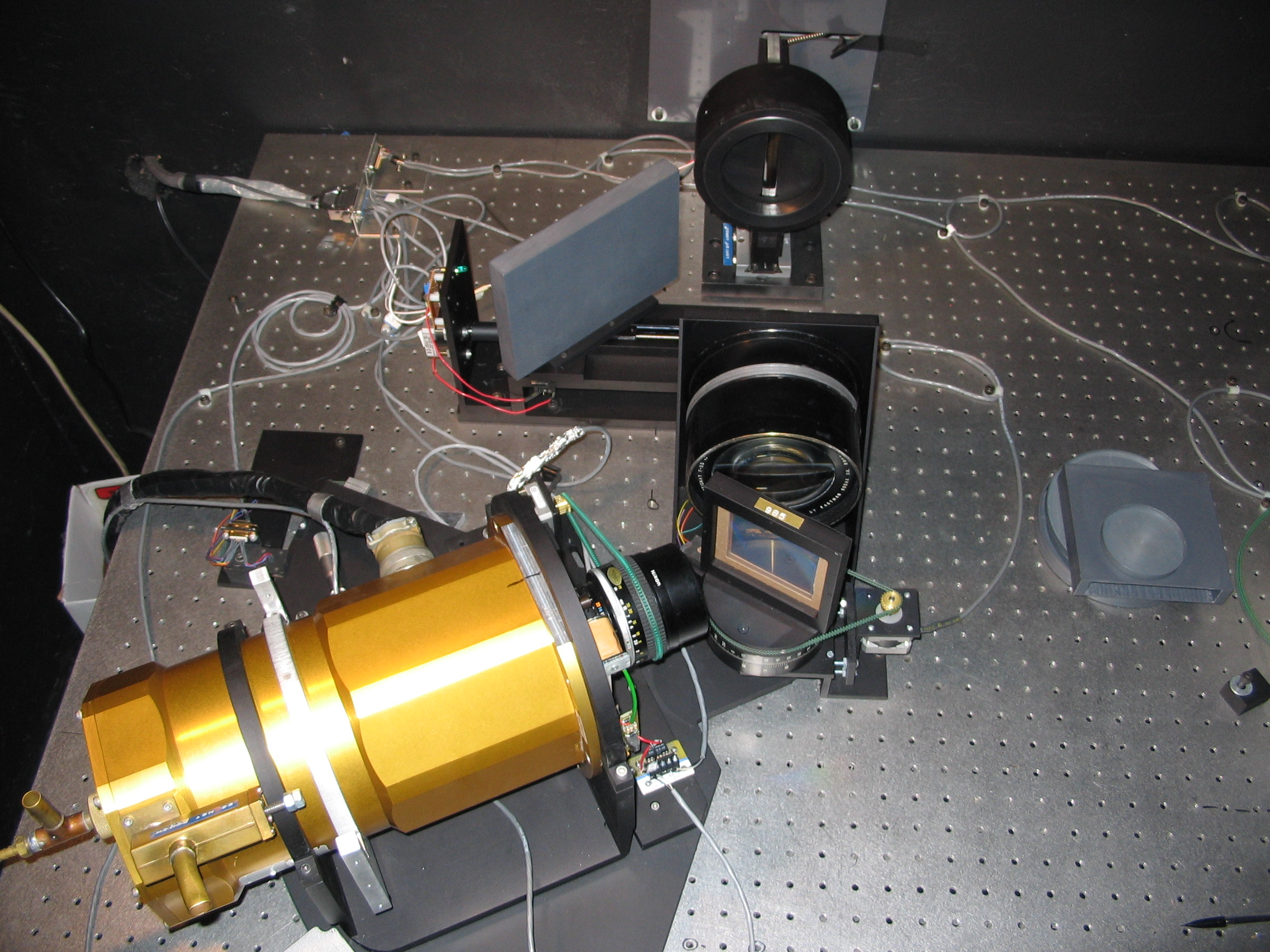

Mechanical Design

The 293 fibers result in a long slit and hence a large off-axis

angle as seen by the collimator and camera. The need to minimize

vignetting vs. slit position and as a function of wavelength requires

a small collimated beam length. Our design features an articulated

camera consisting of a large, 48º sector, 17-inches in radius.

This allows the spectrograph to be configured over a broad range of

wavelengths. An "imaging mode" can be configured by placing

the grating and camera-collimator angles at 0-deg. This configuration

is provided primarily for engineering tests but it may prove useful

for confirming target acquisition as well. WIRO-Spec is designed to

be fully stepper-motor controlled. This requires 2 stepper motors to

control the camera and collimator focus and 2 more to control the

grating rotation stage and the camera-collimator angle. An additional

stepper motor is used to control the position angle of the IFU making

a total of 5 motors on the spectrograph. The instrument is mounted on

an optics bench in the spectrograph room. The figures below show the

spectrograph in the spectrograph room.

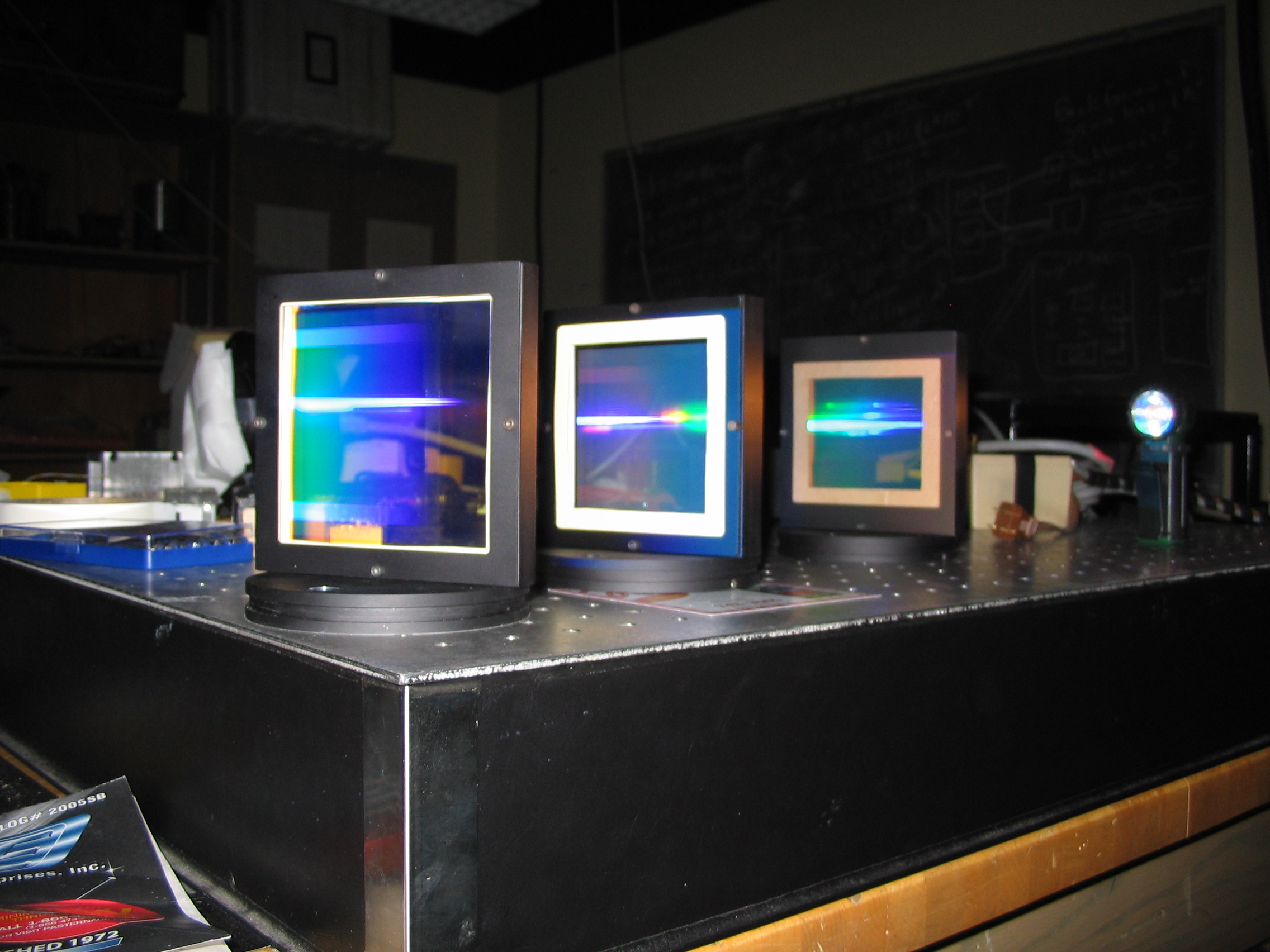

Available

Gratings

Two VPH gratings were kindly provided by

Richard Rallison of Ralcon

Inc. The characteristics

of the two gratings are given in the table below.

|

Grating

|

nu

|

Wavelength

|

Optimal

Angle

|

Efficiency

|

|

2400l/mm

|

2400

l/mm

|

4500

A

|

32º

|

85%

|

|

Ralcon-1

|

1435

l/mm

|

6500

A

|

28º

|

85%

|

|

Ralcon-2

|

985

l/mm

|

8500

A

|

25º

|

85%

|

Instrument Control

Interface

The graphical user interface (GUI) was

designed and programed under Visual Basic 6 by M. Pierce and P.

Haynes. The interface communicates over ethernet to a Compu-motor 6K8

stepper motor controller, allowing the user to select the desired

wavelength and focus the camera and collimator. The figure below

shows the WIRO-Spec GUI. The GUI controls both the spectrograph

configuration and the Guiding and Acquision Module (GAM).

The right side of the GUI is associated with the GAM and the left

side is associated with the spectrograph. The uppermost text box of

the spectrograph control shows the IP address of the 6K8 controller

and the two buttons immediately underneath allow the user to

connect/disconnect to/from the 6K8. The spectrograph GUI allows the

user to select the currently mounted grating from a pull-down menu.

The desired wavelength can then be entered into the text box. The

corresponding grating and camera-collimator angles are computed using

the grating equation. The spectrograph components are then configured

by pressing the go button. The software will then ask the user

to verify that the spectrograph clamps are released before the

components are positioned. The starting and desired wavelengths as

well as the grating and camera angles are displayed in the text boxes

and the components begin to move. The button at lower right will turn

green once the spectrograph components are correctly positioned.

Finally, the software computes the position angle of best focus for

the CCD dewar relative to the camera in order to allow for the small

focus variations with wavelength present in typical camera optics. At

the present time the user must set the micrometer to the computed

position manually in order to achieve the optimum focus. Once the

components are positioned, the camera focus can be adjusted via the

jog buttons. Note that the spectrograph camera focus is very

sensitive to temperature variations and it should be checked at the

beginning of each night using the calibration lamps. It is expected

that the collimator focus will rarely have to be changed.

FITS

Header Editing

At the present time the CCD camera

does not automatically communicate with the telescope control system

(TCS). However, Bob Berrington has written a program to

communicate the telescope information to the Voodoo header.

Otherwise, the Voodoo interface allows the user to edit some the FITS

header parameters. Since Voodoo does not communicate with the

instruments in use and not all of the appropriate KEYWORDS are

automatically written into the header the user is advised to keep

paper logs and/or fill out the header KEYWORDS themselves using the

Voodoo editing tool. Log sheets are available here.

Measured

Performance

Measurements of the individual components

of the spectrograph imply that the overall system throughput should

be about 40%. However, on-sky measurements of spectrophotometric

standards indicate that the efficiency is actually only 15%. The

discrepancy has been traced to a larger focal-ratio degradation than

expected. That is, the output beam from the fibers forming the slit

is faster than expected and light is lost at the collimator. We are

currently investigating the possibility of using an array of

micro-lenses to improve the situation. Stay tuned for updates. Some

spectral images and extracted spectra can be found below.

Last

Modified 05/04/06

Michael

Pierce (mpierce@uwyo.edu), Andy Monson (amonson@uwyo.edu)